Discover Root Causes of Fleet Issues & Fix Them Fast

- saurabhpandey13

- Jul 16, 2025

- 6 min read

Updated: Jul 21, 2025

Understanding Root Causes in Fleet Maintenance

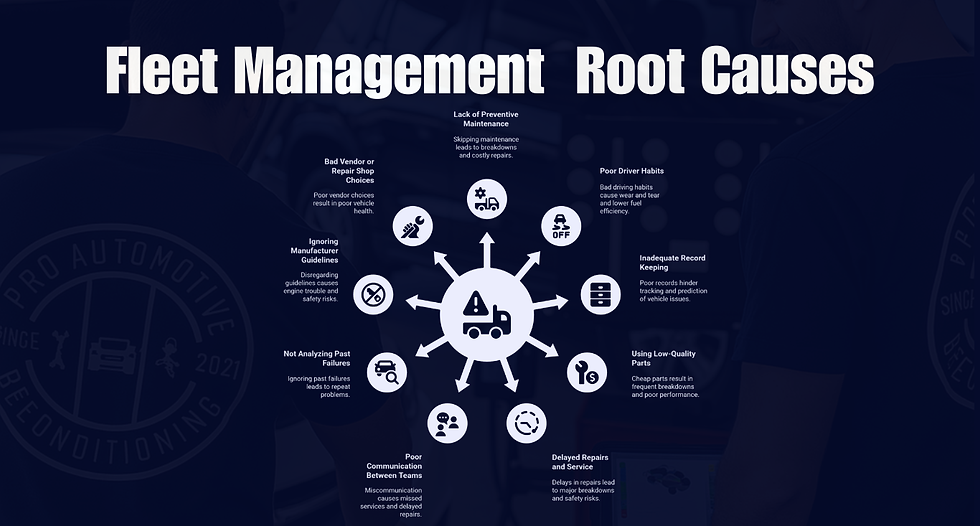

Root causes are the main reasons behind a problem. If you don’t find the real cause, the problem will keep coming back. This is very true when managing a fleet of vehicles. A small issue like a strange noise or late oil change can turn into a big problem later. That’s why it’s important to understand the root causes of common fleet issues.*

When you fix the root cause, not just the symptom, your vehicles stay in better shape longer. This means less time in the shop, fewer costly repairs, and more time on the road. In this blog, we’ll look at the most common root causes that hurt fleet performance and show you easy ways to fix them. This will help fleet managers save time, money, and reduce stress.

What Are Root Causes in Fleet Maintenance?

A root cause is the true reason a problem happens. If a truck keeps breaking down, the real issue might not be the part that broke. It could be poor maintenance, low-quality parts, or missed inspections.

For example, if a tire keeps going flat, the problem may be more than just a nail—it could be uneven wear from bad alignment. By finding the root cause, you solve the real issue, not just the result. This helps your team make smart decisions and keep your fleet running smoothly.

Root cause analysis means asking "why" until you get to the base reason. This saves money in the long run by stopping repeat issues and avoiding guesswork.

Root Cause #1: Lack of Preventive Maintenance

One of the biggest root causes of fleet problems is skipping regular maintenance. Preventive maintenance includes oil changes, brake checks, and fluid top-ups. These simple steps help stop big problems before they start.

When maintenance is missed, small issues like worn-out belts or dirty filters can cause breakdowns. These breakdowns mean lost time and expensive emergency repairs. Regular checks help spot trouble early.

Fleet managers should have a checklist and schedule for each vehicle. This keeps things organized and ensures every truck gets the care it needs on time. Preventive maintenance saves money, reduces stress, and keeps vehicles safe on the road.

Root Cause #2: Poor Driver Habits

Driver behavior can be a hidden root cause of many vehicle problems. Speeding, hard braking, and overloading vehicles can cause extra wear and tear. Bad driving habits not only damage the vehicle but also lower fuel efficiency.

Fleet managers can help by giving drivers training and feedback. Telematics systems track how each person drives. These tools show when a driver is too rough or careless. With that data, managers can coach drivers to drive more safely.

When drivers understand the impact of their habits, they’re more likely to change. This leads to longer-lasting vehicles and fewer breakdowns. Encouraging safe driving is a smart way to protect your fleet.

Root Cause #3: Inadequate Record Keeping

Another root cause of fleet problems is not keeping good records. Without accurate records, it’s hard to know when a vehicle had its last service or what problems were fixed.

If you don’t track repairs, you might replace the same part over and over without knowing why. Keeping a detailed log helps you spot patterns and predict when a part might fail. This helps with planning and saves money on surprise repairs.

Fleet software can help store all service history and vehicle data in one place. Easy access to this information helps managers make better choices and avoid repeat mistakes.

Root Cause #4: Using Low-Quality Parts

Cheap or off-brand parts may seem like a way to save money, but they often become a root cause of bigger problems. These parts don’t last as long and may not fit well.

Using high-quality, approved parts ensures that the repair will last. Trusted parts also come with warranties and are tested to meet standards. Over time, good parts lead to fewer breakdowns and better vehicle performance.

Always ask your repair provider about the parts they use. Investing in quality now avoids costly failures later. Your fleet is only as strong as the parts you put in it.

Root Cause #5: Delayed Repairs and Service

Waiting too long to fix a small issue can lead to big trouble. This delay is a common root cause of major breakdowns. A minor leak or noise might not seem urgent, but it can grow into a big repair if ignored.

Fleet managers should encourage quick reporting and action. When a driver notices something wrong, they should report it immediately. Early action reduces the chance of costly downtime.

Quick repairs also help fleets stay safe. A broken brake or worn tire can be dangerous. Fixing problems right away protects your team, your cargo, and other drivers on the road.

Root Cause #6: Poor Communication Between Teams

Fleet maintenance works best when everyone communicates. Miscommunication or lack of updates can be a root cause of missed services or delayed repairs.

Drivers, technicians, and managers should all have a clear way to share information. A digital system or app helps teams report problems, track service, and follow up.

Clear communication avoids confusion and keeps things moving. It also helps everyone feel like they’re part of the solution. When your whole team works together, your fleet runs smoother.

Root Cause #7: Not Analyzing Past Failures

When a vehicle breaks down, the lesson shouldn’t be forgotten. Not looking at past failures is another root cause that causes repeat problems. If the same truck keeps breaking down, it’s time to dig deeper.

Fleet managers should study past repairs and ask “why did this happen?” This process is called root cause analysis. It can show weak points in maintenance, parts, or training.

Using reports, photos, and technician notes helps create a full picture. Solving past problems helps prevent future ones. Learning from the past is key to building a stronger fleet.

Root Cause #8: Ignoring Manufacturer Guidelines

Each vehicle comes with a manual full of useful information. Ignoring manufacturer service guidelines can lead to issues. This is a silent root cause of many failures.

Service intervals, oil types, and part specs are made for a reason. When fleets follow these rules, vehicles run better and last longer. Skipping or guessing can lead to engine trouble or safety risks.

Fleet teams should keep digital copies of manuals and stick to the service schedule. It’s an easy way to avoid big headaches later.

Root Cause #9: Bad Vendor or Repair Shop Choices

Choosing the wrong repair partner can also be a root cause of poor fleet performance. Shops that cut corners or miss issues hurt your vehicle’s health.

Fleet managers should work with trusted vendors that use quality parts and trained technicians. A good repair shop explains what they’re fixing and why. They should also offer warranties and be easy to contact.

Switching to a better provider might seem like a hassle, but it’s worth it. The right partner can save time, money, and stress.

How Root Cause Analysis Saves Time and Money

When you fix the root cause, you solve the problem for good. This leads to fewer repeat issues and less downtime. Vehicles stay on the road longer and work better.

Root cause analysis doesn’t have to be complicated. It just means asking the right questions and tracking problems carefully. With the right tools, like software and checklists, anyone can do it.

Fixing the cause instead of the symptom builds a strong, dependable fleet. That means less stress for you and a better experience for your clients.

Fix Smarter, Not Just Faster

Fleet issues will always happen, but fixing them smartly is what matters. By understanding and fixing root causes, you can reduce downtime, lower costs, and make your team’s job easier.

Simple habits like preventive checks, using good parts, and better communication go a long way. When your whole team is focused on solving problems for good, your fleet becomes stronger and more reliable.

Why Choose Pro Automotive Reconditioning

At Pro Automotive Reconditioning, we help fleets reduce downtime and fix the root causes of vehicle issues. Our expert technicians use high-quality parts, advanced tools, and proven processes. We partner with fleet managers to create custom maintenance plans that work.

From routine service to full repairs, our team is ready to keep your vehicles road-ready. We serve B2B clients across industries and understand what fleet managers need. Contact us today to build a smarter, more reliable fleet with less downtime and lower costs.

Contact us today at (214) 432-5900

Comments